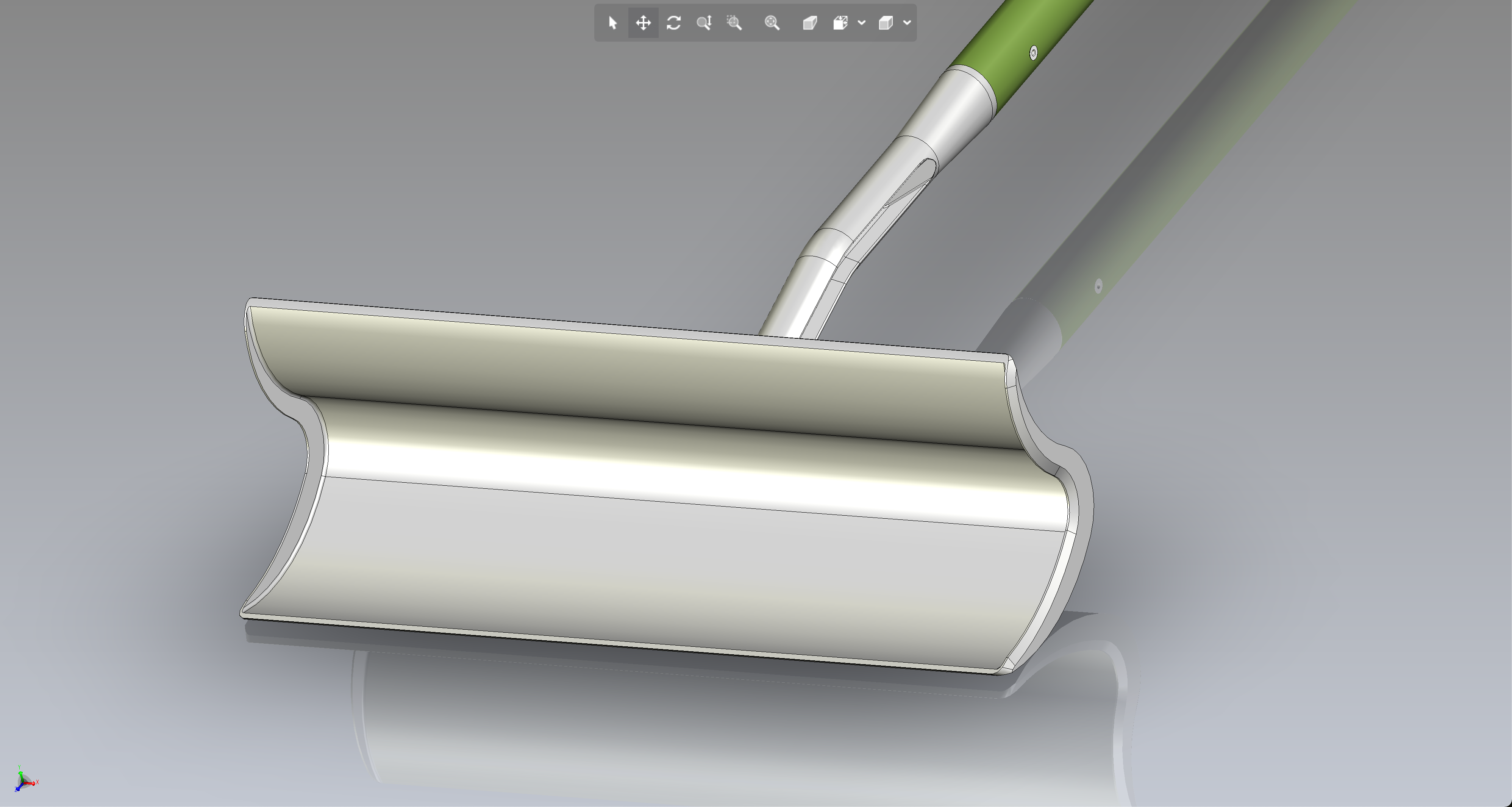

World’s First Double Edge Scraper Tool

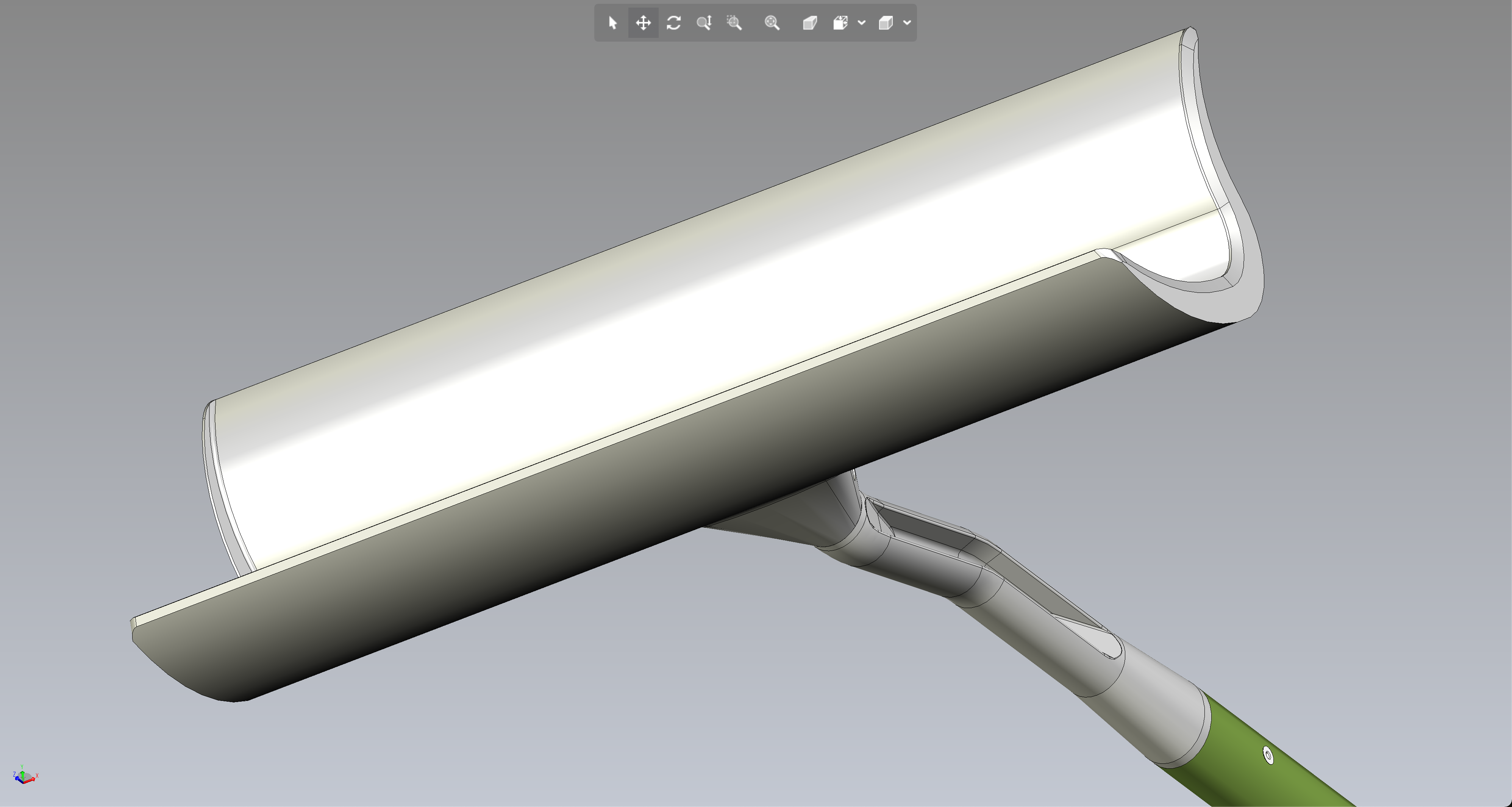

TC Tools GradrBlade scraper tool is the first ever Double Edge Scraper for Industrial, Agricultural and Snow Removal applications.

GradrBlade is twice as effective as conventional tools because you can scrape both toward and away from your standing position. It is especially effective for lifting up and clearing compacted materials. A perfect example is the snow and ice that forms on stairs and sidewalks in high traffic areas.

Removing compressed materials at job sites, or hard pack snow in winter is difficult with a conventional scraper because they only work in one direction. The GradrBlade scraper tool enables you to pull towards you to dislodge material, then reverse direction to plow or scoop it up and clear it away.

$ Avoid The Fine $

Steps and Sidewalks can become a serious Safety Hazard and Liability Issue if snow and ice are not completely cleared away.

Most local governments require property owners to clear adjacent sidewalks after snowfall, or face significant fines. These publicly accessible sidewalks will often become packed down with early morning foot traffic before they can be cleared. This causes the compacted snow to adhere to the porous sidewalk concrete and makes it extremely difficult to clear the surface by merely shoveling.

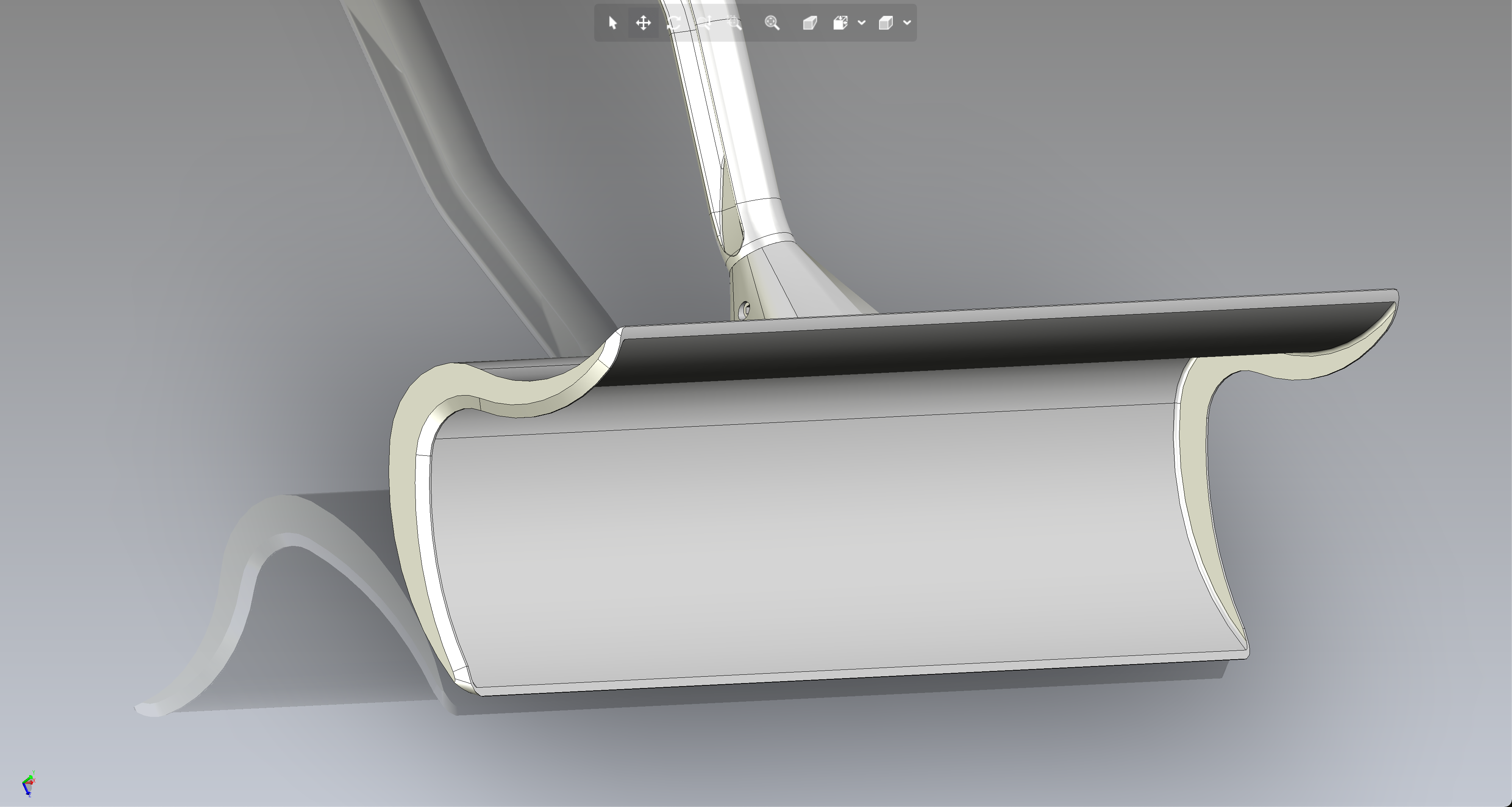

The unique Curvilinear Design of these tools actually lifts the compact snow up and away from the surface. The curvature of the blade peels and breaks up the hard pack snow when pulling toward you. Then by simply rotating the handle and pushing away, the second leading edge scoops it up to easily clear it away.

GradrBlade in Action

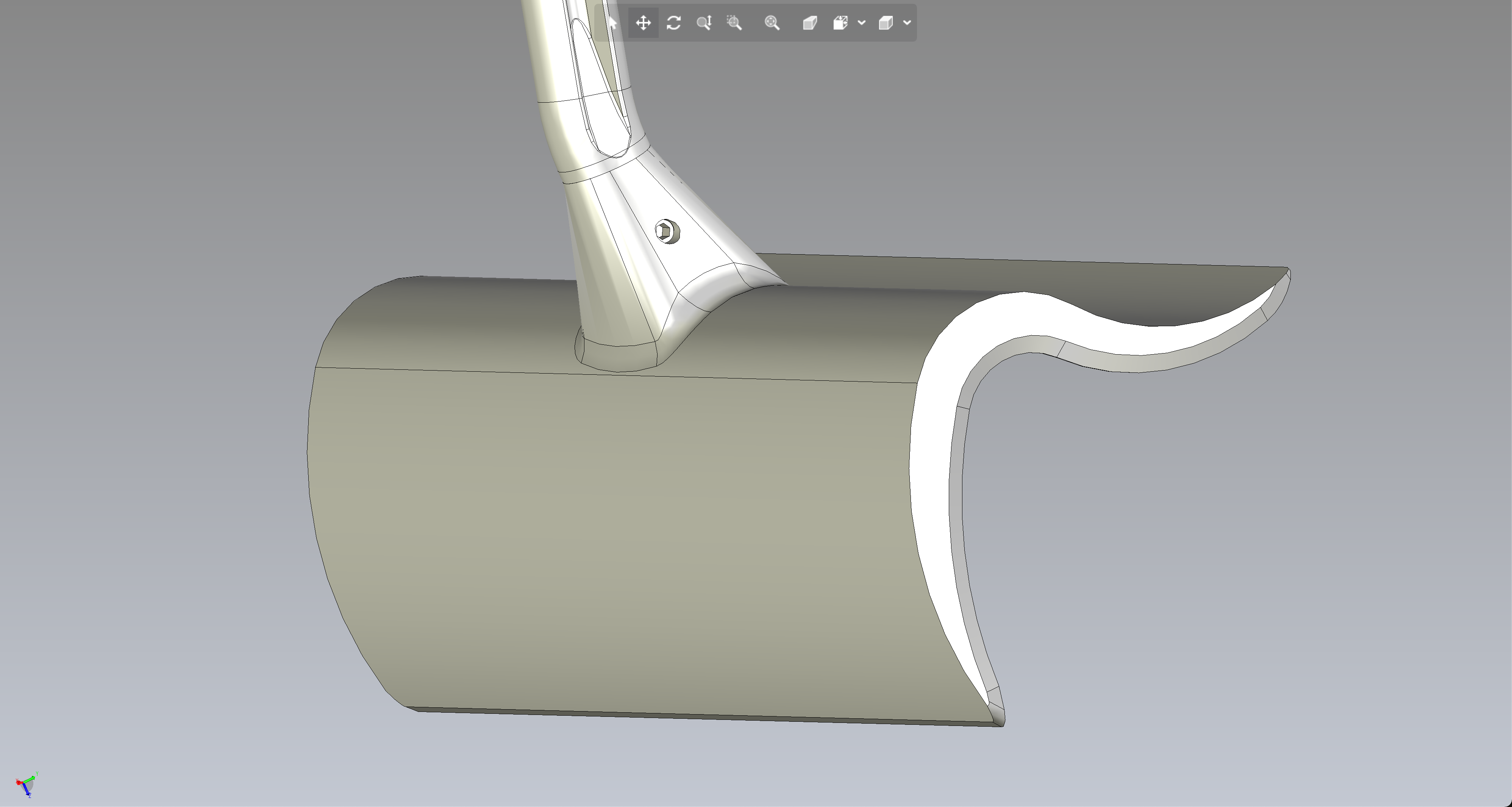

Aluminum Alloy Destructive Testing

To test the durability of the GradrBlade Aluminum Alloy, we used a 3D sand printing process to create a mold. This enabled us to digitally create a sand casting mold to pour a single tool head using the dimensions defined in our CAD engineering diagrams. We could then rigorously test the strength of the alloy before actually going into production.

Because this test tool is cast in sand the surface is not smooth and there are blade and shape imperfections where the sand collapsed. None of these imperfections will occur in the final tooling die.